Knowing Your Lock Nuts | Global Certified Fasteners

Lock nuts, sometimes referred to as stiff nuts, are a special type of nut that don’t loosen when exposed to vibrations. Unlike traditional nuts, which have a basic threaded hole, lock nuts have a unique design that allows them to withstand vibrations. Before lock nuts were invented in the 1930s, companies would simply use two nuts in applications where vibrations occurred, doubling manufacturing costs. The invention of lock nuts provided a more cost-effective solution, reducing the number of needed nuts to one, and increased overall efficiency. Lock nuts also allow multiple objects to be secured together without requiring lock washers.

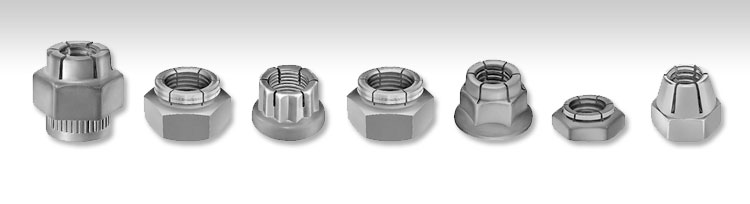

Main Types Of Lock Nuts

- Prevailing Torque

Prevailing torque lock nuts, also known as the stover lock nut, require a considerable amount of torque to tighten or loosen the nut. They must be wrenched in order to be fully tightened or loosened. The two main types of prevailing torque lock nuts are all metal lock nuts and nylon insert lock nuts.

- Metal lock nuts have a crowned top that can be crimped to secure the nut in place.

- Nylon insert lock nuts have a layer of nylon material covering the inside threading, which will expand to grip the bolt.

- Surface Bearing or Tension Induced (AKA free spinning) Surface bearing lock nuts are free spinning and require tightening against a bearing surface for the locking mechanism to function. Two common surface bearing lock nuts are serrated flange lock nuts and KEPS, or K-lock.

- Serrated flange nuts are typically used against metal sheeting. The nuts’ serrations prevent the nut from backing off.

- A key feature of KEPS or k-lock nuts are their free-rolling wings.

- Another type of surface bearing nut is the castle lock nut, or castellated nut. These are typically used in low-torque applications on vehicles, like holding a wheel bearing in place.

What To Consider When Selecting Lock Nuts

There are several things to consider when selecting a specific type of lock nut. First, choose between a prevailing torque lock nut or a tension-induced lock nut. This choice should be made by application. Prevailing torque lock nuts are a better option for shorter assemblies that require resistance to loosening immediately, as well as with more fragile components. Tension-induced nuts should only be used with durable components, and can be applicable in longer assemblies due to their free-spinning nature.

Consider the following characteristics to best select the nut for your application:

- Length of thread exposure

- Size and shape of hole

- Re-use

- Localized corrosion risks

- Exposure to chemicals or extreme temperatures

As with any fastener selection, trust the experts for custom recommendations. The team at Global Certified Fasteners is available to discuss your project’s needs, as well as fulfill your fastener orders, including custom, per print fasteners. Learn more about our selection of nuts, or contact us at (708) 450-9301.