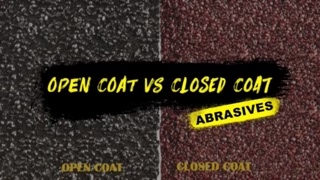

What is the Difference Between Open and Closed Coat Sandpaper?

open coat vs closed coat sandpaper

For those actively involved in the hobby of woodworking and

metal working, the term “coated abrasives” is a common one seen and heard

across the industry, usually accompanied by one of two other terms: open coat

or closed coat. If you are familiar with this term, but unsure how open-coat

and closed-coat abrasives differ, you are one of many. The difference between

the two types of coated abrasives are not only relevant, but also significant, since

using the wrong one will ruin your finish. The decision to use one type of

coated sandpaper over the other is very important, so it requires a little

knowledge and consideration.

Continue reading to learn the difference between

open coat and closed coat sandpaper, and how to find quality coated abrasives

at an affordable price near you.

Closed Coat Sandpaper

If the backing of a sanding belt, sheet, or disc is closed

coated, it means that 100 percent of that backing is covered in abrasive grains;

that means no gaps whatsoever. All surface areas of closed coat abrasives are

occupied with grain, rendering it a strong and aggressive grit. Since their

grains are so closely clustered together, they provide fast, aggressive cuts

and ultra-fine finishes. Closed coat abrasives are recommended for use on hard

materials like hard ferrous and non-ferrous metals, and hard woods like oak and

hickory.

Closed coated abrasives are the most common form of

sandpaper used for finishing and sanding, and should always be used unless you

are working with a softer material like pine or aluminum. Using closed coated

abrasives on softer materials can cause extensive damage to both your work piece

and the sandpaper.

Open Coat Abrasives

Semi-open coated and open-coated sandpaper is simply

abrasives that are manufactured with a lower degree of abrasive grains on their

backing. Compared to closed coat abrasives, semi open coat is modified with 30%

less abrasive grains and open coat is modified with 50% less abrasive grains.

This means they provide a less aggressive, slower cut, and best used for

sanding naturally-soft materials like Aluminum, Pine, Fir, Spruce, Brass,

Copper, and Zirconium.

Purchase Affordable Abrasives Online

Call Sandpaper America at 1-800-860-SAND for information

about coated abrasives and sanding products, today! We offer a large online

inventory of high-quality sandpaper and sanding products at the most

competitive prices online! We manufacture our products in-house, so you can

trust they are high-quality and shipped nationally. Find open coat and closed coat abrasives,

belts, discs, rolls, and much more on our Sandpaper America Website, and see

for yourself just how affordable sanding products can be! Call 1-800-860-SAND

for information about our products, bulk shipping, online orders, and more, any

time.

![[How to] Transform Outdoor Dining Spaces with Counterbalance Hinges](https://fencepliers.top/wp-content/uploads/2023/12/20231218063012-657fe6f439238.jpg)