steel nuts – How to select right steel nuts for your project – industry nuts

Steel nuts are widely used in the construction industry. A small nut is very important in construction engineering. It is generally used with bolts, screws, and washers. It is a common form of fastening. It plays the role of fastening and locking through the installation of nuts and bolts.

These fasteners are required for heavy machinery and other equipment that are often subject to vibration structures. If there is no fastening effect of nuts, the bolts and screws will fall off, and the machine will have major accidents. In light cases, it will stop production for maintenance, and in serious cases, it will lead to property losses.

Next, I will introduce the features and functions of nuts. If you start planning to purchase nuts for your project, our recommendation will be of great help to you.

The shape of an ordinary nut is hexagonal. Hexagon nuts are the most common and cheapest type and are used in many general-purpose products. There is a threaded hole in the center of the nut. What we call the nut size is the diameter of the threaded hole.

If you are a common household fastener, we recommend choosing a nut of grade 4 or grade 6. If it is an important part of mechanical equipment, it should choose a high-grade nut, such as grade 8 or grade 10.

Since different types of nuts are used in construction projects, you need to choose the correct nut type, size, grade, and surface treatment. Here are some specific types of nut applications.

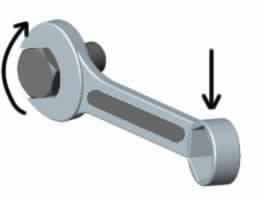

Lock steel nuts

This type is most suitable for the engineering which is easy to vibrate, and the anti loosing effect is remarkable. They provide resistance to vibration forces. They also have different styles, but most of them have the same purpose.

Wing steel nuts

A nut with wings on both sides that can be tightened or loosened by fingers. These features make it easier to adjust, even if used by hand. This type is ideal for construction projects and needs to be tightened or relaxed frequently.

Square nut

This type of nut usually has a larger surface than a hexagon nut. This function makes it easier to grip with a wrench. In some cases, workers weld square nuts to the machine.

Slotted nut

It is also an effective tool in projects where vibration may affect material efficiency.

The slotted nut’s function is to fix the front and rear wheel axles of the vehicle by fastening the screw through the front and rear wheel axles, so that the frame and tire are fixed together. To prevent the nut from loosening, the slotted nut must be fixed through the slot of the slotted nut with a cotter pin. To fix the slotted nut with the cotter pin, the slotted nut must pass through the middle of the wheel axle screw, The diameter of the hole and the groove width and depth of the slotted nut determine the specification of the split pin. When the selected axle screw and the split pin and the slotted nut are relatively matched, the nut will fix the front wheel and the frame through the axle screw and the split pin will fix the slotted nut through the hole fastener of the axle screw so that the slotted nut will not loose So that the vehicle does not loose when moving.