Machine Shops Industry

Personal Protective Equipment

Machine Shops Industry

Machine shops provide a pivotal role in metal fabrication, automotive, aircraft, shipbuilding and other industries that work with metal, metal parts and engines. A machine shop can craft special parts, machine and mill existing parts, and more. For example, when a crankshaft has score marks on it, a machine shop can “turn” it to remove the score marks.

Many machine shops also have a “hot tank,” which has chemicals for cleaning the oil and grease off engines and parts.

List of Equipment for Machine Shops

Some of the equipment you’ll find in a machine shop includes:

- Band saws.

- Drill presses.

- Grinders.

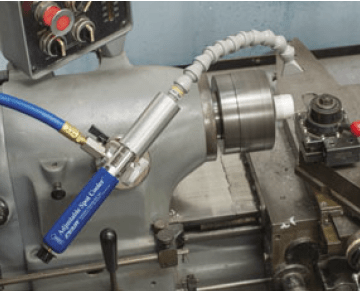

- Lathes.

- Milling machines.

- Table saws.

- Head and block resurfaces.

- Boring machines for boring engine blocks.

- Valve guide and seat machine.

- Hole punchers.

- CNC machines.

These machines have guards and safety features, but you still need personal protective equipment (PPE) when operating them. Shards of metal could fly into your eyes or even cut your hands. The chemicals used in a machine shop could leave chemical burns on your skin and cause cancer. Abolox carries PPE to protect machinists, including gloves that are resistant to chemicals seeping through, face protection, and eye protection.

List of Employment and Occupations in the Machine Shop Industry

As of 2021, machinists made a median salary of $47,940 per year, according to the Bureau of Labor Statistics. The same year had 407,700 jobs. The BLS expects another 3,900 jobs to open up by 2031. You don’t need special education to be a machinist. However, it does take a lot of on-the-job training to become a good machinist.

Other occupations in the machine shop industry include:

- Assemblers and fabricators: Over 1.8 million people in the United States assemble and fabricate parts and pieces, tools, and heavy moving parts. Of this number, about 12,000 work in machine shops.

- Cutting, punching and press machine setters: These workers operate machines that punch, crimp, slit, shear, bend, notch and straighten metal. Job titles might include machine setter, die setter, press operator, or press punch operator. About 5,700 of these workers work in machine shops.

- Grinding, lapping, polishing and buffing machine operators: Workers use grinders to remove burrs and excess metal material. About 1,400 deburreres, grinders, finishers, and grinding operators work in machine shops.

- Inspectors, testers, sorters, samplers and weighers: Workers in these jobs are usually referred to as quality technicians, pickers, pacers, and inspectors. About 9,400 work in machine shops – they inspect assembled, machined and fabricated parts.

- Industrial machinery mechanic: Workers repair, install and adjust machinery. They also cut and weld metal while repairing broken parts. About 2,900 workers in this occupation work in machine shops.

- Industrial maintenance worker: Workers change parts, lubricate machines, and perform maintenance on the machinery. About 7,700 work in machine shops. They work with cleaning solvents, metalworking fluids and oily parts.

- Laborers and material movers: Workers perform general labor and move materials by hand. They might work on loading docks and in warehouses to move materials to production areas. About 3,400 work in machine shops.

- Lathe and turning machine operators: Workers replace worn spools, use cutter-grinding machines, and sharpen dull cutting tools.

- Machinists: Workers create precision parts by operating machine tools.

- Machine tool cutting setters and operators: Workers operate forming and cutting machines. Their titles might include CNC operators, CNC machine setters and CNC machinists.

- Computer-controlled machine operators: Workers use computer-controlled machines and robots to create metal or plastic pieces. About 23,000 work in machine shops. Titles might include machine operator, brake press operator, or CNC operator.

- Material moving worker: Workers help move material through factories.

- Milling and planing machine setters and operators: Workers operate milling and planing machines to plane, profile, mil, and groove metal. About 2,300 of them work in machine shops.

- Welding, soldering, and brazing machine operators: Workers operate soldering, welding and brazing machines and heat treat metal products. About 16,000 work in machine shops joining metal components, adding material to work pieces, and annealing finished work pieces.

- Welding cutters and fitters: Workers weld or join metal components using flame cutting, hand soldering, hand welding and brazing equipment. About 13,000 work in machine shops. Depending on the job, a worker might use this equipment to weld while standing or lying flat for overhead positions.

Safety in Machine Shops

The equipment – both hand and machine – that workers in the machine shop industry use are all dangerous. You can suffer cuts, thermal burns, chemical burns, and more. Wearing the appropriate personal protective equipment significantly minimizes the risk of suffering injuries while working.

Abolox carries much of the PPE a machine shop worker requires to stay safe. PPE includes:

- Gloves, including FR, chemical protection, and touchscreen gloves.

- Safety glasses and goggles.

- Face protection.

- Welding clothing.

- Coveralls.

- Hi-vis clothing.

- Cooling products.

- Steel toe boots.

- Fire-resistant clothing.

- Ear protection.

Visit Abolox

When looking for quality personal protective equipment for yourself or your workers, browse our pages for everything you need. You can order for one person or in bulk if you are outfitting your whole crew. If you don’t see what you need, contact us, and we will source it for you.