Adjustable Spot Coolers

What is a Spot Cooler? Well to fully understand that let’s take a dive into what a Vortex Tube is, since at its core an Adjustable spot cooler is a Vortex tube with some bells and whistles that make them easier to use!

The operation of an Vortex Tube is one of the more curious phenomena in fluidics, and a particularly unique method of producing cold air. Since they don’t perform “heat transfer” in the classical sense (see below), there’s no RATE of heat transfer…they’re generating cold air, at rated flow and temperature, instantly.

EXAIR Corporation’s Vortex Tubes come in a range of sizes & cooling capacities, and are integrated into a number of Spot Cooler Products which add convenience and flexibility to their operation.

EXAIR’s Adjustable Spot Cooler incorporates this Vortex Tube technology to produce temperatures ranging from -30°F – +70°F. At a sound level of just 73 dBA when operated at 100 psig and stock generator installed, this compact cooler will keep your operation cool, clean and dry without causing unnecessarily high noise levels.

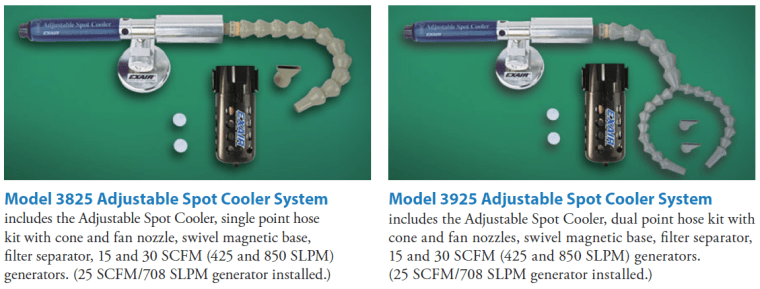

Through a simple turn of the control knob, you can easily adjust the temperature of the unit. Additionally, the kits come with (2) extra generators (15-H and 30-H) that can be swapped out for the stock generator for more/less cooling power and air consumption. The 15-H generator will deliver up to 1,000 Btu/hr of cooling capacity and the 30-H will provide up to 2,000 Btu/hr of cooling capacity. We have (2) different kits available, Model 3825 Single Point and the Model 3925 Dual Point Kit. The 3825 is recommended for use in applications where you’re cooling a small surface such as solder joints, hot melts, or drilled plastics.

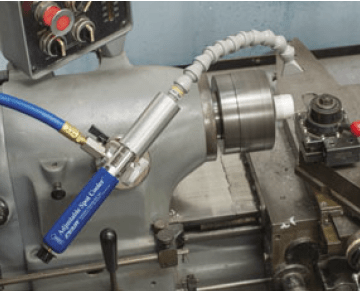

The 3925 system is better served when heat is generated over a larger surface area such as saw blade cooling. The kits use flexible Loc-Line hose to allow you to precisely position the cold airflow onto your target. The Adjustable Spot Cooler provides easy mounting with a swivel magnetic base, allowing you to mount the cooler directly at the most critical point that heat is being generated.

If you’re tired of cleaning up your coolant or have an application that requires dry machining, or you just need to cool something hot! Get one of the Adjustable Spot Cooler systems on order today. They’re in stock ready to ship!

Jordan Shouse

Application Engineer

Send me an Email

Find us on the Web

Like us on Facebook

Twitter: @EXAIR_JS