What is an Abrasive Flap Disc and Do I Need It?

An abrasive flap disc is used for metal fabrication. They

provide grinding, blending, and finishing with just a one tool attachment, and

at a lower cost. Over the last ten years, they have been the fastest growing

category in the abrasives industry. Essentially, they work well to reduce

gouging and burning since they cut cooler. This makes them a preferred choice

among metal fabricators, and for good reason. Not only are flap discs lighter

in weight and easier to control, but they also have less downtime for product

changes.This reduces vibration, noise,

and even fatigue.

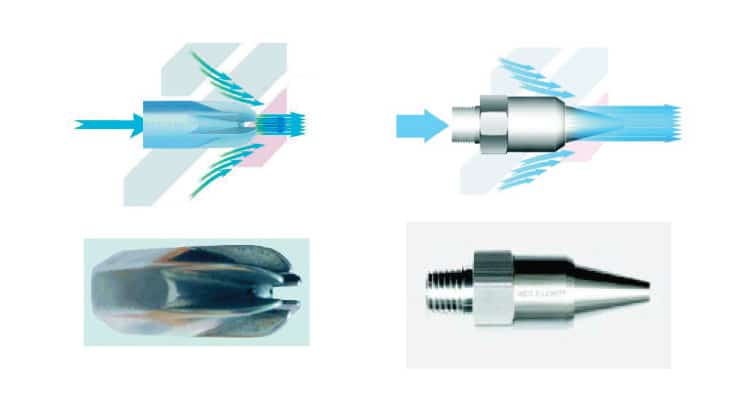

Flap Disc Types

Flap discs are mostly used on right-angle grinders, so they

are specially designed with a hub that allows metalwork to be done on the face.

And the flaps can be used at both an angle and flat. Choosing the right flap

disc shape is vital to your finished product.

There are two primary shapes of

flap discs: Type 29 Conical and Type 27 Flat. Each flap disc shape provides

different performance features, so it is important to choose the proper one for

your metalworking project. Review the differences below to learn the

recommended applications for each.

Type 29 Conical flap discs are recommended for removing

heavy layers of stock. Since they have angled flaps, they can be used for both

edge and contour work. Angled flaps allow for greater surface area contact,

making them the perfect choice for stock removal on flat surfaces. When you are

in need of speed, and stock removal, Type 29 flap discs are the way to go.

Type 27 Flat flap discs are recommended for finishing metal

on flat surfaces. Although they can be used for simple edge work. When you are

just looking to blend, smooth, and finish metal, Type 27 Flat flap discs will

be your best option.

Abrasives for Metal Work

With an abrasive flap disc, you’ll need the proper grit

sandpaper. As for metal work, there are three recommended types of abrasives to

use: 1) Aluminum Oxide, 2) Ceramic Alumina, and 3) Zirconia Alumina. These

abrasives are designed to shape and smooth metal. Use aluminum oxide sandpaper

for smaller projects, ceramic alumina for stainless steel or high-alloy

materials, and zirconia alumina for carbon and mild steel applications.

Are you ready to stock up on some new metalworking

materials? Contact

Sandpaper America at 1-800-860-7263 (SAND) to buy high-quality metalworking

products like Cloth

X-Weight Belts, Flexible

J-Weight Belts, and several other kinds of cloth

metalworking wide belts. We offer custom orders, bulk orders, reoccurring

orders, invoicing, and much more!

Related Posts:

Which

Sandpaper Grit Do I Use on Metal?

How

to Use Steel Brushes to Finish Metal

The

Correct Sandpaper Grits for Sanding Car Paint