Key Stock – A Precision Product

- Previous blog

- Next blog

- Tim O’Keeffe, CEO

- 11/02/2016

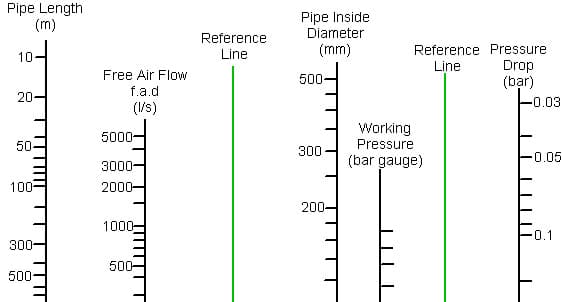

May 16, 2017 Categories Ask Les Tags Recognizing the effect of pressure drop in your compressed air system is essential to ensure your equipment is working optimally. Except for possibly compressed air leaks, the greatest waste of using compressed air is not addressing unnecessary pressure drops. Pressure drop is when pressure loss occurs inside a…

11 February 2022 <!– escapeHtml($post->getPostTitle()) “/> –> Share In October, we reported on the rising aluminium prices and many marketing experts predicted this would continue throughout 2022 and for years to come. Figures released in early February have confirmed that the cost of aluminium has reached its highest level since 2008. The increase in cost…

Weber Knapp Careers | Making Your Passion Your Work Posted by Weber Knapp on Aug 22, 2022 2:07:10 PM Tweet You’re an innovator who loves solving problems. You have a mechanical aptitude and a drive to be creative. You find challenges exhilarating. If you find yourself nodding your head so far, we’d love to show…

Selection Of Elastic Diaphragm Couplings Diaphragm Coupling is a kind of high-performance metal Flexible Coupling, which compensates axial and angular displacements by the deformation of elastic diaphragm while transferring torque. It features with compact structure, large transmission torque, long service life, maintenance-free, high temperature resistance, acid and alkali resistance, and corrosion resistance, suitable for shafting…

#259 – Fire Extinguisher Recharges: Learn When, Why, and How to Get One June 7, 2023August 29, 2019 Proper inspection and maintenance ensure your fire extinguishers are ready for use in an emergency Fire extinguishers are the first line of defense against small fires, and they must remain fully charged or pressurized to be effective…

by Larry Melone President [email protected] Custom Nuts and Bolts Fasteners Distributor Fastener Fastener Distributor Fastener Industry Headcote Headcote Screws Heavy Hex Bolts Heavy Hex Screws Hex Cap Screws Industrial Fasteners Nuts And Bolts Stainless Cap Screws Stainless Steel Fasteners With advancements made in technology, the use of composite materials such as carbon fiber is becoming…