What’s So Great About Compressed Air?

Compressed air is commonly known as “the fourth utility” – along with electricity, water, and gas – due to its ubiquitous use in modern industry. But…why? If you compare the power required to make it, versus the work you can get out of it, it’s abysmally inefficient. And, while it won’t electrocute you, drown you, or blow you up (like the “first three” utilities, respectively), purposely depressurizing a compressed air line comes with its own particular set of risk factors.

Of course, benefits outweigh inefficiencies and risks in many things most of us do every day. Over half of the energy released in your car’s engine goes to heat & friction, instead of turning the wheels. Insurance companies say the typical American driver has a 77% chance of getting into an automobile accident EVERY YEAR, and that most of us will be in up to THREE traffic accidents in our lifetimes. Looking at the number of fellow commuters I saw on my way to work this morning, it’s clear, though, that most of us are ready to accept that inefficiency and risk. And that’s not so surprising, considering they’re mitigated greatly by ever improving technology in fuel efficiency, and safety.

It’s, of course, the same with compressed air use, and the “first three” utilities as well: regulation, training, and engineering lower the aforementioned risks to broadly accepted levels. These disciplines also provide for the most efficient use, in spite of the inherent inefficiencies (no engine is 100% efficient) – getting the most out of what you have is “the name of the game”. So, how does all of this apply to industrial use of compressed air?

SAFETY

- Regulation: In the United States, the Occupational Health & Safety Administration (OSHA) limits the nozzle pressure or or opening of a gun, pipe, cleaning lance, etc., when used for cleaning to 30psi, to protect against dead-ending such a device against your skin, which can cause a deadly condition known as an air embolism. This same directive mandates “effective chip guarding” to keep the blown off debris from hitting the operator. EXAIR Corporation has been in the business of making engineered compressed air products that comply with this directive for almost forty years now.

- Training: There are companies whose sole purpose is to train & certify personnel in both the management, and operation, of industrial equipment in a safe manner. At EXAIR Corporation, our Safety Manager maintains certification from such an agency, which qualifies him to conduct regular training to ensure safe operation of tools, equipment, and chemicals used in the manufacture of our engineered compressed air products.

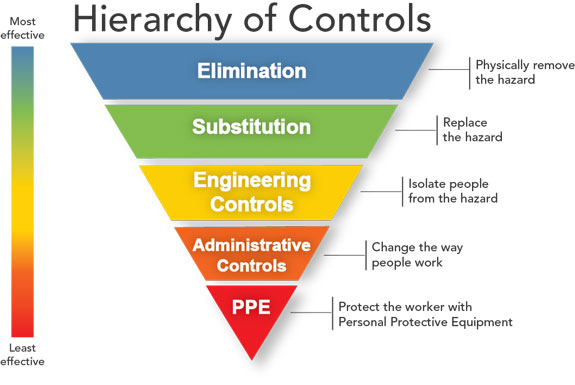

- Engineering: In the “Hierarchy of Controls” established by the National Institute of Occupational Safety & Health (NIOSH), “Engineering Controls” is considered to be less effective than “Elimination” or “Substitution” of the hazard, but more effective than “Administrative Controls” or “Personal Protective Equipment”. THAT’S why EXAIR Corporation has been doing what we do – and why we’re so successful at it – for all this time.

EFFICIENCY

- Regulation: Since the energy crisis of the 1970’s, the United States Department of Energy has implemented numerous initiatives directed at improving energy efficiency. If you’ve ever shopped for a home appliance, you’re likely familiar with EnergyStar ratings. They have a similar program for commercial and industrial air compressors. While they’re not a government body with powers to mandate regulations, the Compressed Air Challenge membership consists of manufacturers & distributors, users, research & development agencies, energy efficiency organizations, and utilities, with key focus on providing direction for the most efficient operation of compressed air systems…from generation to point of use.

- Training: Speaking of the Compressed Air Challenge, they, and other organizations like the Compressed Air & Gas Institute (CAGI) conduct formal training sessions, in addition to the documented direction I mentioned above. CAGI also has a personnel certification program for those interested in developing credibility and confidence by demonstrating knowledge, understanding, and expertise in the design & operation of compressed air equipment. You can even get a cool logo to put on your business cards and in your signature line.

- Engineering: While there are multiple avenues to engineer SAFE compressed air products, not all of them are necessarily efficient as well. At EXAIR Corporation, we set ourselves above the fray by maintaining focus on safety AND efficiency. In their discussion of controls that I mentioned above, NIOSH has this to add on the subject of Engineering Controls: “The initial cost of engineering controls can be higher than the cost of administrative controls or PPE, but over the longer term, operating costs are frequently lower, and in some instances, can provide a cost savings in other areas of the process.” (emphasis mine)

To answer the question I posed in this blog’s title, there are many considerations that make compressed air great to use…among them are:

- Pneumatic tools are lighter, cheaper, more mobile, and lower maintenance than their electrical counterparts. The risk of electrocution is also avoided.

- Compressed air distribution systems are easier and less costly to install than electrical grids or natural gas lines.

- Compressed air doesn’t lose energy over distance like steam.

- Compressed air leaks, while potentially costly, don’t present an inherent safety risk to plant personnel like gas leaks or electrical “leaks” (aka electrocution hazards).

Add in safety and efficiency, and THAT’S what’s so great about compressed air. If you’d like to find out how EXAIR Corporation can help YOU get the most out of our compressed air use, give me a call.

Russ Bowman, CCASS

Application Engineer

EXAIR Corporation

Visit us on the Web

Follow me on Twitter

Like us on Facebook