Split your cold vortex tube

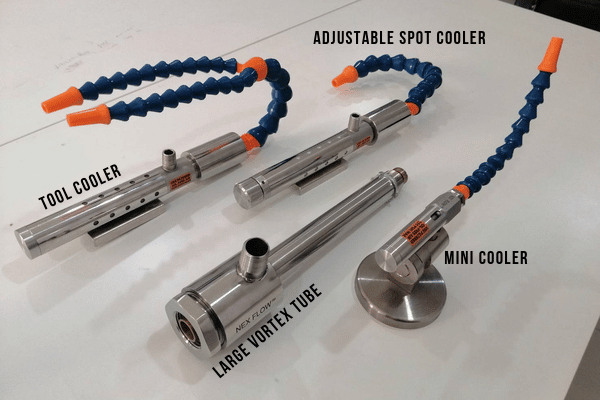

Vortex tubes are ideal for spot cooling and enclosure cooling. Typically one vortex tube is used for one “spot” and for “one” enclosure. But there are some situations where one vortex tube can be split into multiple “spots” as long as one important criteria is kept in mind. Once the compressed air exits the vortex tube it needs to be directed to the area that needs the cooling. When the vortex tube is out in the open, this is achieved by adding a delivery tube, usually flexible tubing to direct the cold air to that spot. When cooling an enclosure, the cold air is sent directly into the enclosure from inside the enclosure. Once the air exits inside the enclosure it can be further distributed around the enclosure thru tubing but all the cold air is input into the enclosure.

Two factors that must be considered when using the cold air produced in a vortex tube: conduction and pressure drop. The general rule it to keep any tubing on an open space vortex tube as short as possible, preferably under 8 inches. One example where a vortex tube has been used in open space for multiple locations is on routing a plastic part. Once Nex Flow Model 50030H vortex tube had the cold air split into two directions and delivered to cool two routers. Rather than using one vortex tube for each router, one larger capacity vortex tube was utilized. If two separate units were used, they could have been smaller capacity units (Model 50015H), each which is ½ the capacity of what was used. What made this work was delivering the air with large (10 mm) tubing to offset pressure drop and keeping the distance as short as possible (under 8 inches to each router). Also, the tubing was insulated to minimize the effect of conducting heat from the surroundings into the tubing, heating up the cold air. There was consideration for using two vortex tubes but there were also space issues with the application.

But this is not a common application. If the distance they had to cool was much longer from the vortex tube, we would have recommended two of the smaller capacity vortex tubes. There is another consideration when considering the use of vortex tubes for multiple location cooling. Let’s take the example above. If the distance from the vortex tube was only a few inches more, to get the same cooling effect at the router, we would have had to use a larger capacity vortex tube, a Model 50040H. That extra 10 SCFM of compressed air use costs energy. That extra energy cost would more than pay for the extra vortex tube in a very short time, and even if used sparingly, certainly in under a year. The increased operating cost, even with minimal use, can easily be equal to or more than the capital cost of one additional unit.

Concerning enclosures, more than once we had to address an issue with cooling when a Nex Flow Panel Cooler, instead of being attached directly to the control panel. Was for some reason mounting off to one side, and a tube was attached to the bottom of the Panel Cooler and then put into the control panel. Needless to say, the unit did not cool as was expected because the cold air heated up several degrees before it reached the control panel. The Panel Cooler has a built in vent to exhaust the displaced hot air inside the cabinet and of course was not used at all when mounted outside. If you are facing any difficulties with installation – please do not hesitate to contact one of our engineers.

Another thing to remember when installing a vortex tube or a vortex tube operated device like the Panel Cooler, onto an enclosure that it must be installed at the top, or if space is lacking, near the top using a side mount. The reason is that cold air falls and hot air rises. The reason a distribution tube is used at the end of a Panel Cooler is to distribute the cold air faster to isothermalize the cabinet (even out the temperature) more quickly. If the vortex tube device is mounted too low, the hot air will tend to stratify at the top of the inside of the enclosure.

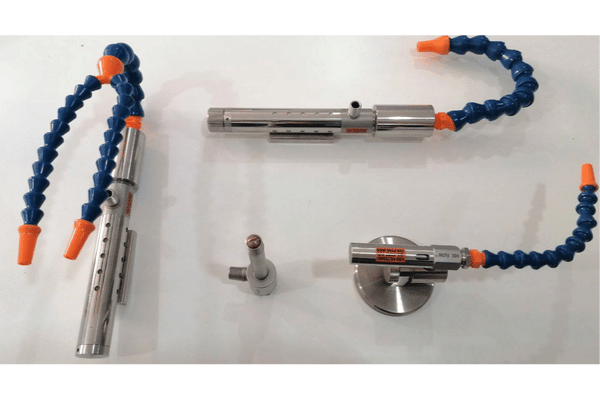

When considering any vortex tube operated device – cabinet enclosure cooler, tool cooler, spot cooler, mini cooler or the vortex tube itself, it is best to keep any attachment at the cold end as short as possible when the product is in open space. When attached to an enclosure of any type, the cold air should be directed directly into the enclosure, near or at the top.