5 Compressed Air Injuries

Compressed Air: 5 Associated Injuries and How to Stay Safe

While compressed air is relatively safe compared to many other sources of power, especially electricity, there are still safety issues that need to be considered with using compressed air. Here Nex Flow shares 5 injuries associated with compressed air operations and how to steer clear of them.

1. The Eyes

The most common injury from the use of compressed air is to the eyes. Compressed air is used by most industries and is often used to blow off and clean work places of dirt and debris. A prominent cause of eye injury is when chips and particles bounce back towards the operator when blowing off or working. This is often not stressed enough, but it can be a huge safety risk as the eyes are one vital way for us to sense the environment. Even the smallest of particle has the potential to cause a large injury, especially if correct safety equipment is not readily accessible. As little as 12 pounds of compressed air pressure can blow an eye out of its socket.

According to the United States Occupational Safety and Health Administration (OSHA), up to 90 percent of eye injuries can be prevented with correct safety equipment. When flying chips and particles is part of the work environment, wear safety glasses with side protections. These help to prevent back bouncing particles from getting in behind the safety glasses and cause harm.

Three important things to think about to decrease the risk of eye injuries:

- Work preventively by understanding the nature of the work assigned and minimize the risk of harm

- Identify and eliminate potential risks before diving straight to work. Remember that work screens and other guarding equipment can be used to limit risk area.

- Use proper safety equipment that protects the eyes.

To work without safety in mind in an environment where eye injuries can occur can be very expensive. The annual cost of eye in juries is estimated to be over $300 million per year. To increase safety, and extra protection when blowing off, air guns with safety shields can be used to minimize the risk of chips and particle that can be blown behind safety glasses and cause potential injury.

2. The Ears

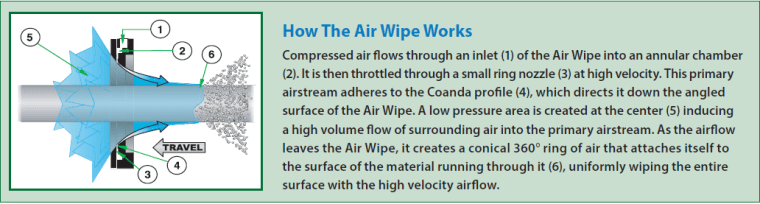

Compressed air noise can cause damage to the ears. Compressed air exhaust noise can be quite noisy when used for blow off or cooling. Blowing with compressed air can result in elevated noise levels that can be harmful to both the operator as well as the surrounding persons. Both short and repeated blowing operations can be harmful and result in hearing damage and tinnitus. The damage can appear gradually, and it can be difficult to determine when and how the hearing problems developed. OSHA’s regulations also affect the approved noise level of a workplace. Open jets and pipe can produce noise levels as high as 90 dBA or more which is very dangerous to hearing even with short term exposure. Learn more about noise levels here. In any factory environment, there are certainly many other sources of noise from moving machinery, grinding of gears, the squeaking and clanging of chains, and banging of parts. Damage from compressed air noise can have serious and damaging effect on your hearing due to high noise exhaust levels. Fortunately compressed air exhaust noise can be addressed by the use of exhaust mufflers on devices such as air cylinders and the use of engineered air nozzles, compressed air amplifiers, and air knives to reduce the noise levels significantly.

3. The Skin and Body

Skin and body damage can also occur from flying debris when using compressed air for blow off or cooling. Blowing to cool a hot part can cause a chip or hot dirt particle to become loose and possibly fly towards and burn your hands and arms. Even small particles can bounce back and at high enough velocity can embed into the skin and cause infection later on, even if not felt immediately. Again not only is the use of eye shields important but it is equally important to wear protective clothing when handling compressed air in a high risk environment. Compressed air accidentally blown into the mouth can rupture the lungs, stomach or intestines. Even with a layer of clothing, compressed air can enter through the navel so be cautious and pay attention to your surroundings when in an industrial environment. It also helps to know and abide by compressed air safety standards.

FEATURED PRODUCTS

Easy Grip Safety Air Gun

X-Stream® Heavy Duty Safety Air Gun

X-Stream® Hand Vac

4. The Bloodstream

A very serious situation occurs when compressed air enters the bloodstream – an aeroembolism. This can happen if the operator is blowing compressed air on themselves or someone else. If the pressure becomes too great or the compressed air is blown directly against the body, the compressed air can get underneath the skin and into the bloodstream.

Compressed air is a concentrated stream of air at high pressure and high speed that can cause serious injury to the operator and the people around him. First, compressed air in itself is a serious hazard. It has been known for compressed air to enter the blood stream through a break in the skin or through a body opening. An air bubble in the blood stream is known medically as an embolism, a dangerous medical condition in which a blood vessel is blocked, in this case, by an air bubble.

An embolism of an artery can cause coma, paralysis or death depending upon its size, duration and location. While air embolisms are usually associated with incorrect scuba-diving procedures, they are possible with compressed air due to high pressures. This may all seem to be improbable, but the consequences of even a small quantity of air or other gas in the blood can quickly be fatal so it needs to be taken seriously. Unfortunately, horseplay has been a cause of some serious workplace accidents caused by individuals not aware of the hazards of compressed air and/or proper work procedures. If an air pocket reaches the heart, it causes symptoms similar to a heart attack. Upon reaching the brain, pockets of air may lead to a stroke. Therefore to stay safe, do not use pressurized air to blow on yourself and other personnel, and avoid horseplay when working with compressed air.

5. Faulty Equipment

Another danger to be aware of when using compressed air is with hoses and quick disconnects. Leaking or damaged hose or connectors can be quite dangerous as they could break. Under pressure broken hoses or hoses that come loose from the system because of failed connectors can whip around and cause serious injury. If people are working with old or frayed hoses, air may leak out causing a pressure drop. This lack of pressure can cause machines to malfunction and other problems. If the hose is damaged and then pressurized it could cause injury when it ‘explodes’ outward. This sudden release of the pressure can cause a machine to engage or disengage, resulting in injuries to the operator and bystanders.

To stay safe, check the hoses regularly and never – of course – use frayed, damaged or deteriorated hoses. Worn connectors and hoses should be replaced immediately. Store hoses safely, away from heat and sunlight to prolong the product lifetime. Hoses are best stored on a hose reel for longer life, and to avoid tripping hazards.

Compressed air is still one of the safest and friendly utility to use with many advantages. But while relatively safe, certain precautions as listed above are still necessary so you can safely enjoy the benefits of compressed air.

![[How to] Transform Outdoor Dining Spaces with Counterbalance Hinges](https://fencepliers.top/wp-content/uploads/2023/12/20231218063012-657fe6f439238.jpg)