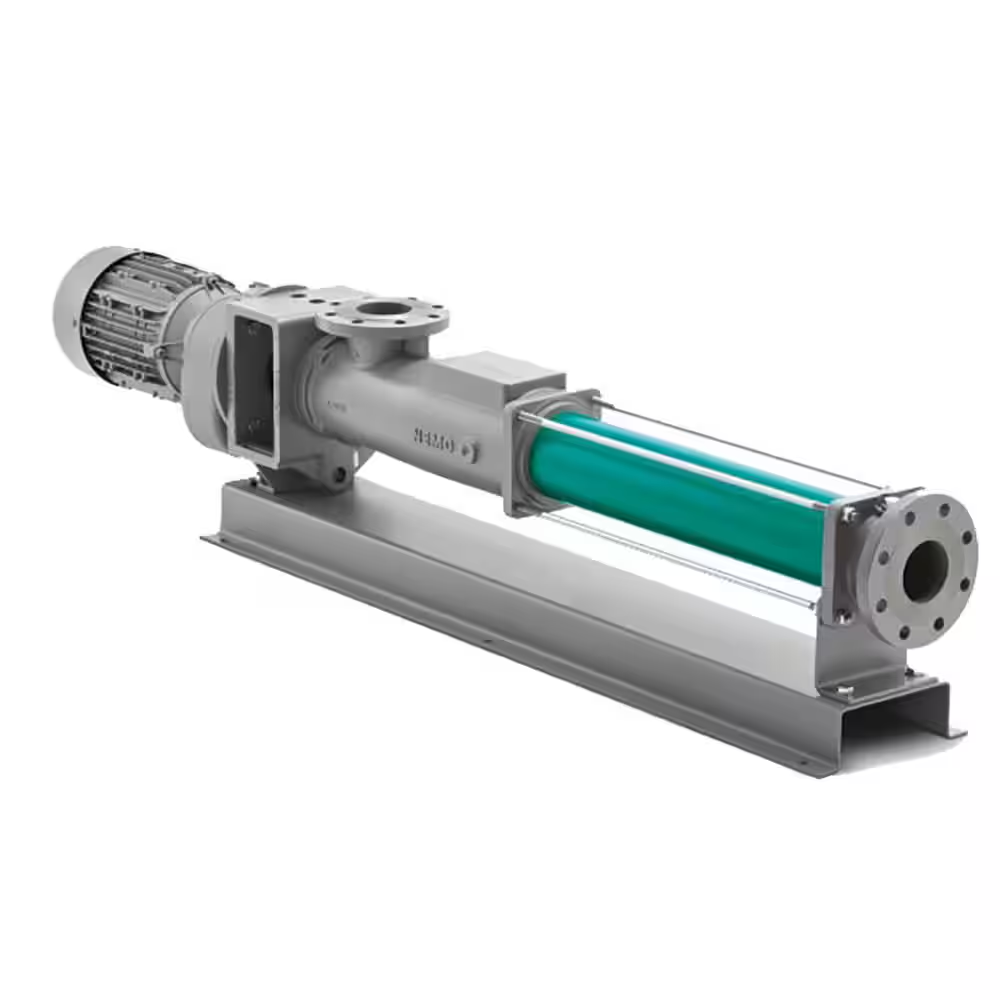

What Maintenance is Required for the Netzsch NM038BY?

The Netzsch NM038BY is a highly efficient machine designed for various industrial applications. To ensure its optimal performance and longevity, regular maintenance is essential. This article will outline the key maintenance practices required for the Netzsch NM038BY, including daily, weekly, and monthly tasks.

Daily Maintenance

Daily maintenance is crucial for the smooth operation of the Netzsch NM038BY. Here are some essential tasks to perform each day:

- Visual Inspection: Check for any visible signs of wear or damage on the machine components. Look for leaks, cracks, or unusual noises during operation.

- Clean the Machine: Remove any dust, debris, or residue from the machine’s surfaces. This helps prevent buildup that could affect performance.

- Lubrication Check: Ensure that all moving parts are properly lubricated. This reduces friction and wear, contributing to the machine’s efficiency.

- Fluid Levels: Verify that all fluid reservoirs, such as oil and coolant, are at appropriate levels. Refill as necessary to prevent overheating or mechanical failure.

Weekly Maintenance

Weekly maintenance tasks help to maintain the performance and reliability of the Netzsch NM038BY. Consider the following activities:

- Filter Inspection: Check and clean or replace filters as needed. Clogged filters can restrict airflow and lead to overheating.

- Belt and Chain Tensioning: Examine the tension of belts and chains. Adjust as necessary to prevent slippage or excessive wear.

- Electrical Connections: Inspect all electrical connections for signs of corrosion or wear. Tighten any loose connections to ensure proper functionality.

- Calibration Check: Verify that the machine is calibrated correctly. This ensures that it operates within the desired parameters and maintains product quality.

Monthly Maintenance

Monthly maintenance is more comprehensive and aims to address any potential issues that may have developed over time. Key tasks include:

- Thorough Cleaning: Perform a deep clean of the machine, including internal components. This helps remove any buildup that may have accumulated.

- Component Inspection: Conduct a detailed inspection of critical components such as pumps, motors, and valves. Look for signs of wear and replace any parts that may be nearing the end of their lifespan.

- Software Updates: Check for any available software updates that could enhance the machine’s performance or add new features. Keeping software current is vital for optimal operation.

- Documentation Review: Review maintenance logs and documentation to track any recurring issues. This can help identify patterns and inform future maintenance strategies.

Conclusion

Regular maintenance of the Netzsch NM038BY is essential for ensuring its longevity and optimal performance. By adhering to a structured maintenance schedule that includes daily, weekly, and monthly tasks, operators can prevent costly downtime and extend the lifespan of the machine. Investing time and effort in maintenance not only enhances productivity but also contributes to the overall success of industrial operations.