How to Maintain Progressive Cavity Oem Spare Parts

Progressive cavity pumps are essential in various industries due to their ability to handle viscous fluids and provide a steady flow. To ensure optimal performance and longevity, it’s crucial to maintain the OEM spare parts associated with these pumps. This article will guide you through effective maintenance practices for progressive cavity OEM spare parts.

Understanding Progressive Cavity Pumps

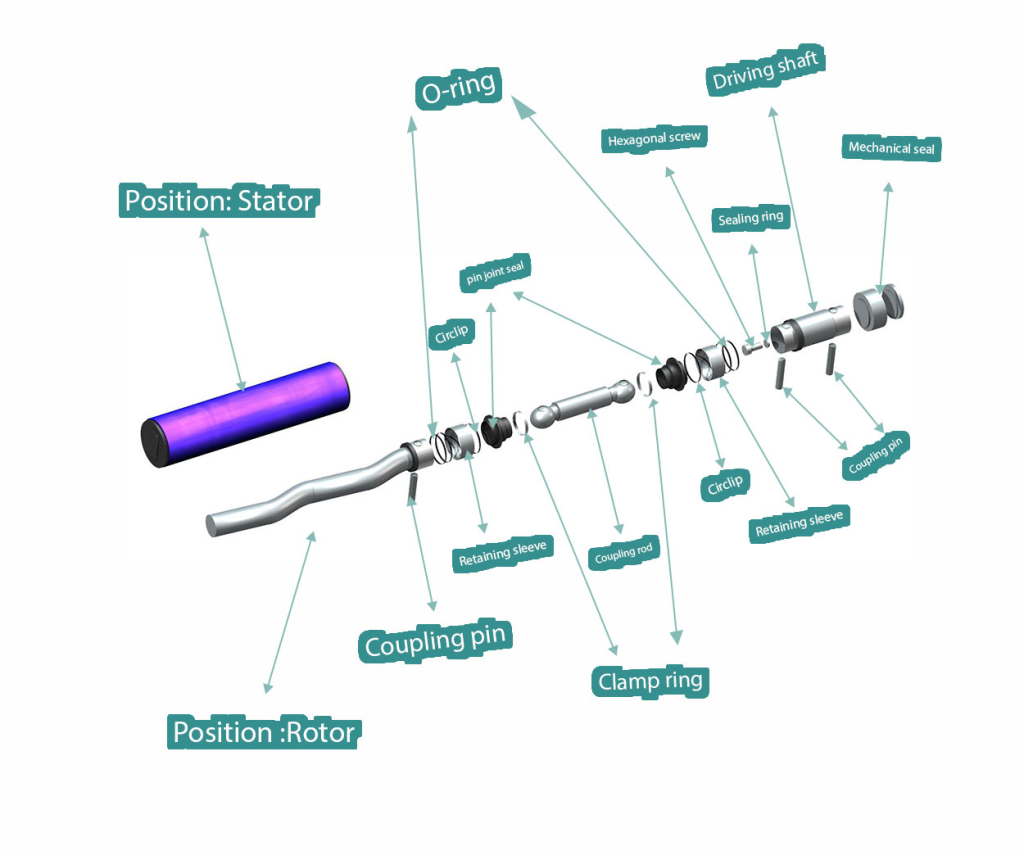

Before delving into maintenance, it’s important to understand what progressive cavity pumps are. These pumps consist of a helical rotor and a stator, which work together to move fluids through a series of cavities. The design allows for a smooth and continuous flow, making them ideal for applications in the oil and gas, food and beverage, and wastewater treatment industries.

Importance of OEM Spare Parts

Using Original Equipment Manufacturer (OEM) spare parts is vital for maintaining the integrity and efficiency of progressive cavity pumps. OEM parts are designed specifically for the pumps, ensuring compatibility and reliability. Here are some reasons why OEM spare parts are essential:

- Quality Assurance: OEM parts meet rigorous quality standards, providing assurance that they will perform as intended.

- Enhanced Performance: Using OEM spare parts helps maintain the pump’s efficiency and flow rate.

- Longevity: OEM parts are built to last, reducing the frequency of replacements and repairs.

Maintenance Practices for Progressive Cavity OEM Spare Parts

To ensure the durability and functionality of progressive cavity OEM spare parts, follow these maintenance practices:

Regular Inspections

Conduct regular inspections of the pump and its components to identify any signs of wear or damage. Check for:

- Leaks: Look for any fluid leaks around seals and joints.

- Wear: Examine the rotor and stator for signs of abrasion or deterioration.

- Alignment: Ensure that the pump components are properly aligned to prevent unnecessary strain.

Lubrication

Proper lubrication is essential for the smooth operation of progressive cavity pumps. Follow these guidelines for lubrication:

- Use Recommended Lubricants: Always use lubricants specified by the OEM to avoid compatibility issues.

- Check Levels Regularly: Monitor lubricant levels and replenish as needed to prevent friction and wear.

- Avoid Over-Lubrication: Too much lubricant can cause buildup and negatively impact performance.

Cleaning

Keeping the pump and its components clean is crucial for preventing blockages and ensuring optimal performance. Implement these cleaning practices:

- Regular Cleaning Schedule: Establish a routine cleaning schedule based on the pump’s operating conditions.

- Use Appropriate Cleaning Solutions: Choose cleaning agents that are safe for the materials of the pump components.

- Inspect for Residue: After cleaning, inspect for any remaining residue that could affect performance.

Replacement of Worn Parts

Even with proper maintenance, some parts will eventually wear out and need replacement. Here are some tips for replacing worn parts:

- Follow OEM Guidelines: Always refer to the OEM’s recommendations for replacement intervals and procedures.

- Use OEM Parts: When replacing components, ensure that you use OEM parts to maintain compatibility and performance.

- Document Replacements: Keep a record of any parts replaced along with the dates to track maintenance history.

Proper Storage of Spare Parts

If you have spare parts on hand, proper storage is key to maintaining their condition. Consider the following:

- Climate Control: Store spare parts in a climate-controlled environment to prevent degradation from extreme temperatures or humidity.

- Organized Storage: Keep parts organized and labeled to easily access them when needed.

- Regular Inventory Checks: Periodically check your inventory to ensure that parts are in good condition and ready for use.

Training and Awareness

Training personnel who operate and maintain progressive cavity pumps is essential for effective maintenance. Ensure that staff are aware of:

- Operating Procedures: Proper operation minimizes wear and tear on the pump and its components.

- Maintenance Protocols: Regular training sessions on maintenance procedures help reinforce best practices.

- Safety Measures: Educate staff on safety measures to prevent accidents during maintenance.

Conclusion

Maintaining progressive cavity OEM spare parts is crucial for the longevity and efficiency of pumps. By following regular inspection routines, ensuring proper lubrication, cleaning, replacing worn parts, and storing spares correctly, you can significantly enhance the performance of your progressive cavity pumps. Training and awareness among staff further contribute to effective maintenance practices. By investing time and resources into these efforts, you can ensure that your pumps operate smoothly and reliably for years to come.