Engine Manufacturing Industry

Personal Protective Equipment

Engine Manufacturing Industry

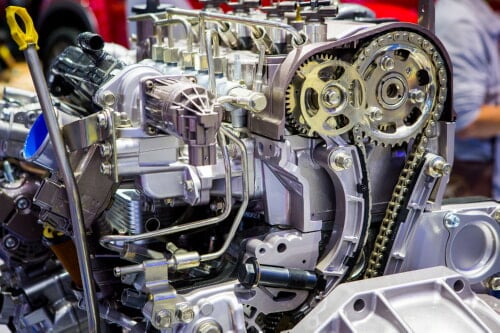

Without an engine, your car isn’t going anywhere – unless you want to be like Fred Flinstone and power it with your feet. The engine manufacturing industry not only makes engines for passenger vehicles but it also makes engines for planes, boats, helicopters, large trucks, and large equipment.

The engine manufacturing industry makes gas-powered engines for passenger vehicles. It also makes diesel engines and electric engines for diesel cars and trucks.

Engine Manufacturing Work Activities

Work activities in the manufacturing sector include:

- Working with coolants and lubricants.

- Assembling hydraulic systems.

- Assembling electromechanical systems.

- Cleaning parts.

- Cutting materials, including metal and fiberglass.

- Drilling metal.

- Handling hot objects.

- Assembling heads, engines and transmissions.

- Operating grinding and metal forming equipment.

- Operating hoists, hand tools, jacks, and cleaning machines.

- Painting.

- Mounting cables, wires, and engine accessories.

- Installing pistons, bearings, camshafts and other engine parts.

- Sanding and grinding.

Tools in the Engine Manufacturing Industry

Those in the engine manufacturing industry use a variety of tools, including sockets, ratchets, wrenches, screwdrivers and more. In many cases, engines are built on an assembly line with little input from a line worker. However, skilled auto technicians can rebuild a complete engine. Most must send the engine to a machine shop to press bearings in and hot tank the block.

The machine shop sends the engine back, and the auto technician installs the pistons, rods, rings, crank, camshaft, springs, valve keepers, valves, and many other internal parts.

Once the engine is in the vehicle, the tech installs the accessories, including the distributor, spark plugs, exhaust manifolds, starter, alternator, battery, power steering pump, air compressor and related parts, radiator and related parts, water pump and more.

Tools commonly used in the engine manufacturing industry might include:

- Knives.

- Scrapers.

- Pliers.

- Screwdrivers.

- Wrenches.

- Sockets.

- Ratchets.

- Extensions.

- Presses.

- Torque wrenches.

- Drills.

- Sanders.

- Pry bars.

- Ring keepers.

- Punches.

- Hammers.

Die Casting the Engine Block

To make the block, factories use large machines – presses and other machines to form the shape of the engine block. Metal – cast iron or aluminum – is melted at high temperatures and poured into the forms.

When the blocks are done, workers remove excess material from the forms and add other parts as needed, depending on the manufacturer. The process is much more complicated than that, but it shows that workers are working with sharp materials, large equipment, and scalding metal. The melting point of aluminum is 1,221 degrees Fahrenheit. The melting point of cast iron is 2,200 degrees Fahrenheit.

Safety

Whether an engine manufacturer works in a factory die casting blocks or in a shop putting engines together, they are exposed to hazards from hot materials, large equipment, and fast-moving tools. Even hand-held tools such as screwdrivers can pose a hazard, especially if someone uses them incorrectly. For example, using a screwdriver to pry something could cause it to slip and puncture the person using it.

Some of the personal protective equipment used in the engine manufacturing industry include:

- Hi-vis clothing might be required by some manufacturers.

- Safety glasses and goggles in manufacturing plants and vehicle repair shops.

- Cooling products when working outside or in buildings that are not air-conditioned.

- Safety coveralls for all workers.

- Welding clothing to protect against welding sparks and other sparks.

- Head protection including several types of hard hats.

- Safety gloves for puncture, abrasion, and chemical protection.

- FR clothing, especially when working around hot metal. FR clothing also protects workers against flash fires.

- Ear protection, especially when working in a factory die casting blocks or working with air tools. Even drills make a lot of noise that could damage your ears over time.

- Other personal protective equipment, including face protection (shields).

Contact Abolox

When looking for quality safety equipment and personal protective equipment for excellent prices, visit Abolox. We carry only known brands made of quality materials. You can order most items as individual items or in bulk. If you don’t see what you are looking for, call the office, and we will source the items for you.